It’s what’s on the inside that counts, but it’s amazing what good packaging can do for your product.

The way your product is packaged plays a surprisingly key role in how consumers respond to it. Good packaging can elevate your brand, justify a high price point, and serve as a key distinction between yourself and your competitors — and that’s just the beginning.

To understand why packaging is so important, you have to understand what your packaging communicates. There are a few fundamental elements of your product packaging: shape, design, materials, colors, and text. Each element communicates something about your brand both on its own and in relation to the entire package. These are things like:

- Your brand’s voice and values.

- Who your product is marketed to.

- What your product does.

Your packaging also inherently communicates other things, such as its market value and — strange as it may seem — who the consumer can become if they use the product.

Ultimately, product packaging is about marketing. The way you choose to design your packaging will help consumers differentiate between your products and other similar products and assist you in building brand recognition over time.

Well-designed packaging can also sway consumer behavior in your favor. For example, 72% of consumers say that the way a product is packaged affects their purchasing decision, with even more (81%) saying it influences their gift selections.

If you acknowledge packaging for what it is — an ad for your product that lives right with it on the shelf — it becomes clear that there’s no room for error. Good packaging can make a noticeable difference on your bottom line, and it’s up to you to ensure that you end up with packaging that sells.

Read on to learn everything you want to know about picking the perfect packaging for your product. We’ll cover the types of packages and boxes you should consider, custom print effects, how to communicate your ideas to your printer, and more.

Determining the Basics of Your Package Design

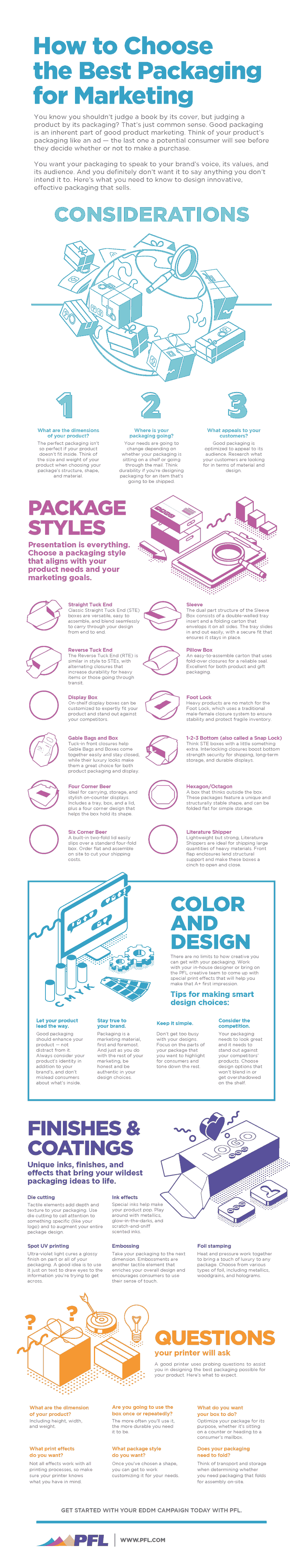

Before you can select the best packaging for your product, you need to make some decisions up front. Start with these questions to help narrow down your options and clarify what direction you should go in:

1. What material do you want to use?

Your choice of material is one of the most important parts of your packaging design. Whether you go the paper or plastic route depends on your brand’s style and the product itself, though keep in mind that, overwhelmingly, consumers prefer paper packaging. 68% of consumers say they’re more likely to choose a product in a paper or cardboard package versus a plastic package, and 63% say paper packaging makes a product seem more high-quality.

2. How will your product be transported?

Durability is tantamount to successful packaging, and function and ease of transport should be considered when coming up with your package design. You don’t want to design original and eye-popping packaging only to have it lose its shape before it gets to its end location.

3. What is your budget?

As with most marketing strategies, budget is going to have a big impact on what you can and cannot do. When coming up with your spending limit, make sure to budget not just for the packaging itself but also for the creative work that goes into designing it.

4. What will appeal to your desired customers?

This is one of the biggest areas you need to define when coming up with your packaging plan. From the materials to the colors, each aspect of your packaging needs to be optimized to appeal to its intended audience. Spend time researching what will make the biggest impact with your key demographics and incorporate your findings into your final design.

12 Package Styles

There is no shortage of styles when it comes to packaging. Choose one that aligns with your answers to the questions in the last section, and that works well with the size and shape of your product as well as the overall presentation that you are going for. Here are

1. Straight Tuck End

Versatile and easy to assemble, Straight Tuck End (STE) boxes are an excellent option for streamlined packaging. Fold/tuck closures on both sides make for a simple and effective seal. Closures are positioned toward the back and blend seamlessly along the edges to maintain a clear design across the entire box.

2. Reverse Tuck End

Reverse Tuck End (RTE) boxes are similar in style to STE boxes, but instead of both closures sealing in the back the top closure seals in the front. The alternating closures enhance the durability of the seal, making RTEs good choices for heavier items or those that may shift around in transit.

3. Display Box

Display boxes come in a range of sizes and shapes to help your products stand out on the shelves. Optimize your display box to best fit your product, your display area, or both, with plenty of options for ensuring that your products are both well protected and well positioned to sell.

4. Gable Bags and Box

One of the leaders in luxury packaging, gable bags, and boxes feature a steady structure and a tuck-in front closure that helps them come together easily and stay closed. Use Gable Bags and Boxes for product packaging or display.

5. Four Corner Beer

Four corner beer packaging — which includes a tray and a box with a lid — features a classic four-corner design wherein each side folds inward to hold its shape. This structure is ideal for carrying and storage, and it also makes for stylish on-counter displays.

6. Six Corner Beer

The six corner beer is a riff on standard four corner beer packaging, consisting of a four-fold box and a two-fold lid that easily slips over the box when folded down. Boxes can be shipped flat for practical storage and put together on site.

7. Sleeve

A sleeve box uses a dual part structure to create a highly durable packaging solution. Double wall tray inserts slide effortlessly into a folding carton that envelops the insert on all sides. Trays can be opened at either end and are securely fitted to prevent them from slipping out when you don’t want them to.

8. Pillow Box

It’s easy to see how the pillow box got its name. These basic cartons are easy to assemble, with a one-piece design and foldover closures on each end. While not great for stacking, pillow boxes make for innovative product and gift packaging.

9. Foot Lock

Also known as the walker lock, foot lock trays feature a traditional male-female lock design that ensures stability once constructed. Features four fixed flaps that hold together separately from the main lock design. Good for storing and organizing large inventories and heavy items.

10. 1-2-3 Bottom (aka Snap Lock)

1-2-3 bottom boxes also called snap lockboxes, offer a similar look to tuck end boxes with additional bottom strength security provided by interlocking closures. Additional locks or friction can be applied to the boxes for increased durability.

11. Hexagon/Octagon

For those who want to get a bit more creative with the shape of their packaging, hexagon and octagon boxes offer similar security to square, rectangular, and pillow boxes, plus a stand-out silhouette. Despite their unique shape, hexagon and octagon boxes can be folded flat for storage and are a good fit for a wide variety of products.

13. Literature Shipper

Literature shipper boxes are lightweight but strong, making them sturdy options for shipping large quantities of books, product samples, brochures, and more. An outside front flap enclosure makes for easy opening and closing and lends structural support where it’s needed most.

Custom Packaging

All of our packaging solutions and designs can be completely customized to fit both your product and your brand. Companies across a wide variety of industries are using custom packaging as an innovative way to add a distinct touch to their products, particularly products that look similar from manufacturer to manufacture.

Custom packaging can enhance the entire experience of your product for a consumer. In the cannabis industry, for example, recently formed companies who want to get ahead of their competitors on the market with custom packaging that plays around with structure, design, and even smell. Digitally produced packaging components help ensure that branding doesn’t interfere with regulatory labeling requirements, while modern design techniques and packaging shapes help redefine cannabis and what it means to purchase it.

Another industry taking custom packaging to the next level is mail subscription boxes. Companies that offer monthly or quarterly product selections for consumers are shipping focused — meaning their packaging has to be durable and can’t vary too much in shape. To stand out, many subscription boxes play around heavily with design, custom creating boxes for each shipment so that recipients are as intrigued by the package they receive as they are about what is inside of it.

And perhaps nowhere are we seeing more expressive custom packaging than among e-commerce companies. Online-only stores rely on their packaging for both efficient shipping and to enhance the value of their brand, which can be difficult to convey in a website. By getting creative with their packaging, e-commerce companies help build a brand identity off of the web — a major objective for products that you aren’t going to just come across in a store’s aisle.

Custom Print Effects

The only limit to a company’s creativity with their packaging is their imagination. Today’s custom print effects can make pretty much any packaging idea come to life quickly and affordably. Learn a bit more about our custom print effects and how to turn your dream packaging design into a reality.

Ink Effects

Custom ink effects add a ton of personality to your brand packaging and are incredibly useful for maintaining a cohesive marketing message across various brand materials.

Think beyond the standard CMYK process when selecting colors for your product packaging. Custom ink and coating is a relatively simply printing effect that uses a variety of specialty inks to make your product pop. Custom inks include metallics, and scratch-and-sniff scented varieties.

Die Cutting

Die cutting adds depth and texture to your packaging with special effects that help you communicate key ideas about your brand and your products. Die cut shapes are created with custom made cutters (think of a steel cookie cutter) that result in finely detailed, sharp edge designs that can augment all of your packagings or call attention to one distinct part of it. Die cuts can also be made digitally.

Other Special Print Effects

Beyond the basics are those effects that don’t fit neatly into a specific category. These include:

- Foil Stamping. Heat meets pressure for a dye-process that adds a luxurious touch to any package. Heated foil is pressed on to the surface and preserved in place with a unique pressure process. Can be used on its own or combined with embossing for a three-dimensional effect. Various types of foil can be used, including metallics, woodgrains, and holograms.

- Embossing. The embossing process brings texture to your packaging with words and designs subtly popping off the package for a truly eye-catching look. The embossment can be the same color as the rest of the packaging, or dies — including lavish metallic foils — can be used to enhance the look even more.

- Spot UV Printing. With Spot UV, ultra-violet light is used to cure a glossy ink or coating on your packaging. The result is a shiny print effect that is excellent for highlighting key text on your packagings, such as your logo or the name of your product.

The sky’s the limit when it comes to your custom print effect options. Work with our design team for creative solutions to any effects you may want to add.

Questions Your Printer Will Ask

Your printer is the one responsible for taking your packaging ideas and turning it in to a completed product. As such, packaging design is mostly a collaborative effort. Be prepared to answer key questions that will help your printer establish guidelines for your packaging and ensure that the package you picture in your mind is what you end up with.

Question 1: What are the exact dimensions of your product?

The most important thing about your package is that your product fits inside of it. While package sizes can certainly extend far beyond the dimensions of your product, this answer will establish the minimum size of your packaging and may suggest that your product would work better in some box structures better than others.

Question 2: Is this a one-time use box, or something you’re going to use repeatedly?

You’re going to want a different box for packaging that’s used often (such as a box of cards) versus packaging that’s used just once (such as a box for shipping). Your answer to this question helps to establish the structure and the substrates (materials) that make up the basis of your packaging design.

Question 3: How heavy is the item you will be putting inside the package?

Similar to your product’s dimensions and the use frequency of the package, the weight of your product is going to have an effect on the structure and materials your printer uses. For example, if your product is heavy you may need corrugated paper rather than a folding carton to ensure that everything stays in place.

Question 4: Is there some commonality between different products that need packages?

You can save a lot of money by ordering one box for various products and customizing them with labels, stickers, or print effects. Various color swatches can also be used to differentiate different products on the shelf while using only one box structure. If you and your printer can find a commonality, you can simplify the packaging process by ordering more boxes from the start and then working to distinguish between them later on.

Question 5: What do you want your box to do?

This question is a biggie. Considerations for your packaging will differ depending on if your package will sit on the shelf or display table or if it’s going to be going through the mail.

Question 6: What coatings/textures do you want?

Custom print effects are incredibly versatile, but not all effects work with all printing processes. You’ll want to know what sorts of custom inks, coatings, textures, etc. you want for your package before you finalize your box order.

Question 7: What shape of box do you want?

By this point, your printer will know more than enough about your package requirements to help you narrow down an ideal shape. If you don’t want a standard square or rectangle, consider custom box options such as pillow boxes, hexagons, or other unique shapes.

Question 8: Do you need your packaging to fold?

If you’re going to be putting together packaging on site it’s a good idea to order boxes that fold for easy shipping and storage. It’s also good for your bottom-line since flat boxes are considerably cheaper to ship. It’s important to note however that some folding boxes cannot support as much weight as their non-folding counterparts. You may need to change the base enclosure to accommodate a heavier item.

Be ready with answers to these questions before you first speak with your printer. The same goes for any other specific requirements you have that will be related to your ultimate package structure and design.

Considerations for Designing the Perfect Package

Your packaging needs to serve a lot of purposes — both function-related and style-related. Designing the perfect package comes down to making smart decisions about not just what you want your product packaging to do but what you want it to say (and within your company’s budget, no less).

There is no such thing as one-size-fits-all packaging that works for every product and every brand. What there is, however, is perfect packaging for your product and your brand. Here’s how to figure out what that is:

Start with your product.

It’s the reason you’re designing packaging in the first place, after all. Your packaging needs to be optimized to fit and sell your product — not the other way around. In addition to customizing for fit and design, don’t forget to factor in how your packaging will travel and store.

Look at what your competitors are doing.

It’s a good idea to look at strong brand contenders in your industry to see what they’re doing with their packaging, not to steal their design but to identify some key features that make their packaging so effective. These will include companies that are selling similar products to your own as well as companies who are selling in similar environments. What are they doing that’s working, and how can you use those strengths to inspire your own design?

Consider your customer.

Well-developed customer personas can help you establish everything from what grabs your customers’ eyes on the shelves to the packaging materials they’re most likely to gravitate towards. The customers are the “end users” of your packaging, so you need to make sure to appeal to them with each detail.

Don’t forget about any packaging requirements.

If you have certain labeling that needs to be included on your packaging, incorporate it into your overall design so it doesn’t look like an afterthought. This helps you create one cohesive design instead of a package of competing parts.

Get results and feedback.

It’s okay if you don’t get it right on the first try. While it’s important to maintain your packaging over time for an established brand identity, you don’t want to hold on to a packaging style that’s not working for you. Try to create opportunities for clear feedback from your customer base on whether they like your packaging and what they like about it (or alternately, what they don’t).

Great packaging design is crucial for the success of your business. You should be putting as much thought into it as you did design your product itself, with an eye toward additional functional considerations like durability and transportability.

A big part of creating the right package is working with the right printer. Printing for Less is an industry leader and has been helping businesses create standout custom packaging since 1996.

Ready to take the next step? Email us at info@printingforless.com or give us a call at 800-930-6040 to get to work today on your perfect packaging.